Plastic worm gears Plastic worm gears are suitable for low sliding speeds 15 ms and medium tooth pressure due to their bad thermal conductivity. It covers cylindrical worms with helical threads and wormgears hobbed for fully conjugate tooth surfaces.

Worm Gear Calculation And Design Mitcalc 12 Youtube

Design of peripheral structures of gears 5.

. POM PA 66 Tensile strength R with 23C. αW λ 90. There are no great advances in gear technology described.

12MB Annotated PDF - 12MB 13 Gears strength gear trains Original PDF - 13MB Annotated PDF - 13MB 14 Microcontrollers. PDF In worm gear mechanism power loss is one of the critical issues which requires attention from gear designers and researchers. Sn 5 88 ksi 44 ksi Table 12-1 Y 421 Fs 44000 1 421 8 Fs 2316 lb Use F s 1900 lb for design purposes.

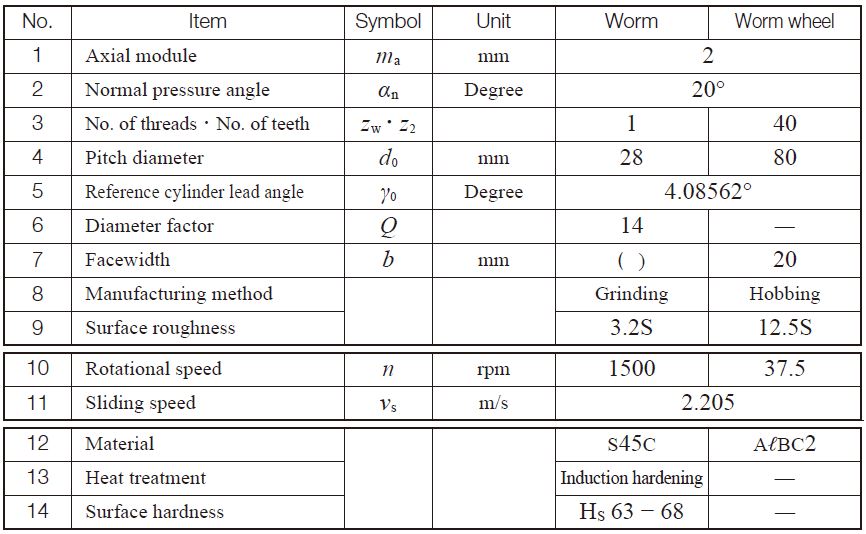

Executing the drawings of the parts related to the gears. Worm gears are used when larggge gear reductions are needed. Now lets say we have the following design input.

85 Years Invested In The Production Of Metric Gears Resulting In World-Class Equipment. The axial pitch of the worm and the circular pitch of the gear must be same for a mating worm and gear. Bevel and Worm Gears 797 158 Designing a Worm-Gear Mesh A usable decision set for a worm-gear mesh includes Function.

Nd Tooth system Materials and processes Number of threads on the worm. It may be noted that the helix angle on the worm is generally quite large and that on the worm gear is very small. Speed of the Worm N1 20 RPM.

Also the module of the worm as well as the gear must be equal for a mating worm and gear. American Standard Design for Fine-pitch Worm Gearing ANSI B69-1977 This standard is intended as a design procedure for fine-pitch worms and wormgears having axes at right angles. The diameter D w of the integral worm has been estimated to be 1875 in.

The efficiency of a worm gear ranges from 98 for the lowest ratios to 20 for the highest ratios. Thus it is usual to specify the lead angle λ on the worm and helix angle αG on the worm gear. If similar process is repeated.

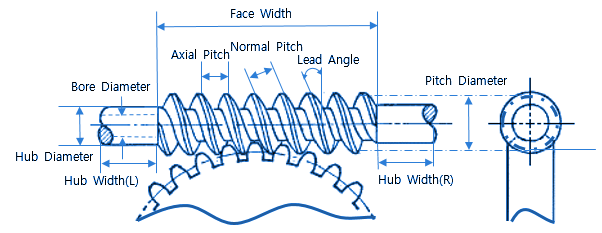

NW Axial pitch of worm. Syllabus Calendar Lecture Notes. Basically a worm gear is a screw butted up against what looks like a standard spur gear with slightly angled and curved teeth.

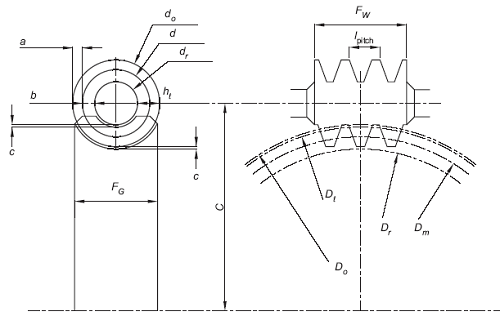

Px Pitch diameter of the worm. P Circular pitch of wormgear P axial pitch of the worm P x in the central plane P x Axial pitch of worm P n Normal circular pitch of worm and wormgear Px cos λ P cos ψ λ Lead angle of worm ψ Helix angle of wormgear. We will use the term Pitch P for both the pitch in this tutorial.

Its history is so old that its existence is described by Archimedes in around 250 BC. DW Face width of gear. Select the number of teeth for the pinion and the g ear to.

Ad Proudly Providing North America With Factory Direct Service For Fast And Easy Shipping. Strength of Gear Teeth contd P N RAO 17 Classes of Gears Transmitted load depends on the accuracy of the gears Gear. The set of a worm and worm wheel is called a worm gear.

Decide upon a pitch and face width that satisfies these requirements. WORM GEAR Worm and worm gear pair consists of a worm which is very similar to a screw and a worm gear which is a helical gear as shown in Fig. The pitch line velocity is ideally up to 30 ms.

Power speed mG Ka Design factor. Worm gearing is not a practical solu-Axlal Movement tion for most applications and other forms of gearing should be. Select number of teeth on worm.

In T able 82 for. Input Parameters Teeth type - common or spiral Gear ratio and tooth numbers Pressure angle the angle of tool profile α Module m With ANSI - English units enter tooth pitch p π m Unit addendum ha Unit clearance c Unit dedendum fillet r f Face widths b 1 b 2 Unit worm gear correction x Worm size can be specified using the. CHAPTER 11 Worm Gears Chapter Outline 111 Introduction 439 112 Force Analysis 446 113 AGMA Equations 449 114 Design Procedure 453 115 Conclusions 455 References 456 Further Reading 456 Nomenclature 457 Abstract Worm and wheel gears are widely used for nonparallel nonintersecting right angle gear drive system applications where a high transmission gearing.

These gears are widely used in current day automobile drive line power transmission. The worm is made of steel with a minimum BHN 250. The gear is bronze.

70 Nmm2 50 Nmm2 m. The worm can easily turn the gear but the gear cannot turn the wormgear but the gear cannot turn the worm. Proportions of worm and worm gear 2.

It changes the rotational movement by 90 degrees and the plane of movement also changes due to the position of the worm on the worm. Design the worm gear if it is made of Phosphor bronze 8. These two angles are equal for a.

Introduction to Gear Design Introduction Albert Einstein once said. There are roughly two types of worm gears. 32 Design Procedure for Selection of worm gears - Using PSG Design Data Book Manufactures Catalogue Step.

Plastic worm gears are suitable for 50 torque of bronze worm gears. Worm gears provide a normal single reduction range of 51 to 75-1. Design procedure for dts revised kamaraj college of engineeing and technology.

For ratios below 3. Strength of Gear Teeth P N RAO 16 Gear. A worm gear is a thread cut into a round bar and a worm wheel is a gear that meshes with the worm at a shaft angle of 90 degrees.

Specifying the pressure angle. It does not cover helical gears used as wormgears. Review of festivity procedures 24 A review of this years machines 25 Course summary feedback Course Info.

Check spur gears strength 4. It is common for worm gears to have reductions of 201 and even up to 3001 or greater Many worm gears have an interesting property that no other gear set has. Clarify specifications and determine basic elements 2.

Equations for American Standard Fine Pitch Worms and Wormgears Per. The ideal ratio range for worm gear-ing is 5. We will use the term Pitch P for both the pitch in this tutorial.

Compare the actual values to the permissible values and repeat process if necessary 14 Determine. Worm gear design parameters. Design shapes of spur gears 3.

Wire rope and sample problem. POM PA 66 Tensile strength R with 23C. I are practical and have applications that are very successful.

Machine Design II Module 2 -GEARS Lecture 1 -INTRODUCTION Contents. Worm diameter factor q helix direction γ. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear design by presenting information from a manufacturing point-of-view rather than a theoretical one.

Worms have to be hardened and ground. Give the required gear ratio observe the guidelines presented. Worm lead angle ie.

A high-efficiency worm-gear speed reducer is desired to accept 20 hp from a 1750-rpm motor. In this series we explain how to design gears and peripheral parts according to procedures using simple mechanisms. Design and Manufacturing I.

Worm gears are an old style of gear and a version of one of the six simple machines. T-XVI-161 And find number of teeth on wheel by Transmission ratio. The worm has 4 threads.

1This is the general range for most catalog reducers. Gears Engineering and Design.

Worm Gear Design Calculation Pdf Merge Peatix

Agma Worm And Spur Gear Design Equations And Calculators

Worm Gearing Classes Proportions Materials And Worm Gear Cutting

Surface Durability Of Worm Gear Khk Gears

Agma Worm And Spur Gear Design Equations And Calculators

Pdf Machine Design Ii Module 2 Gears Lecture 16 Worm Gears Worked Out Problems Contents Aju Joseph Academia Edu

0 comments

Post a Comment